Giải Pháp Cải Tạo Nhà Máy

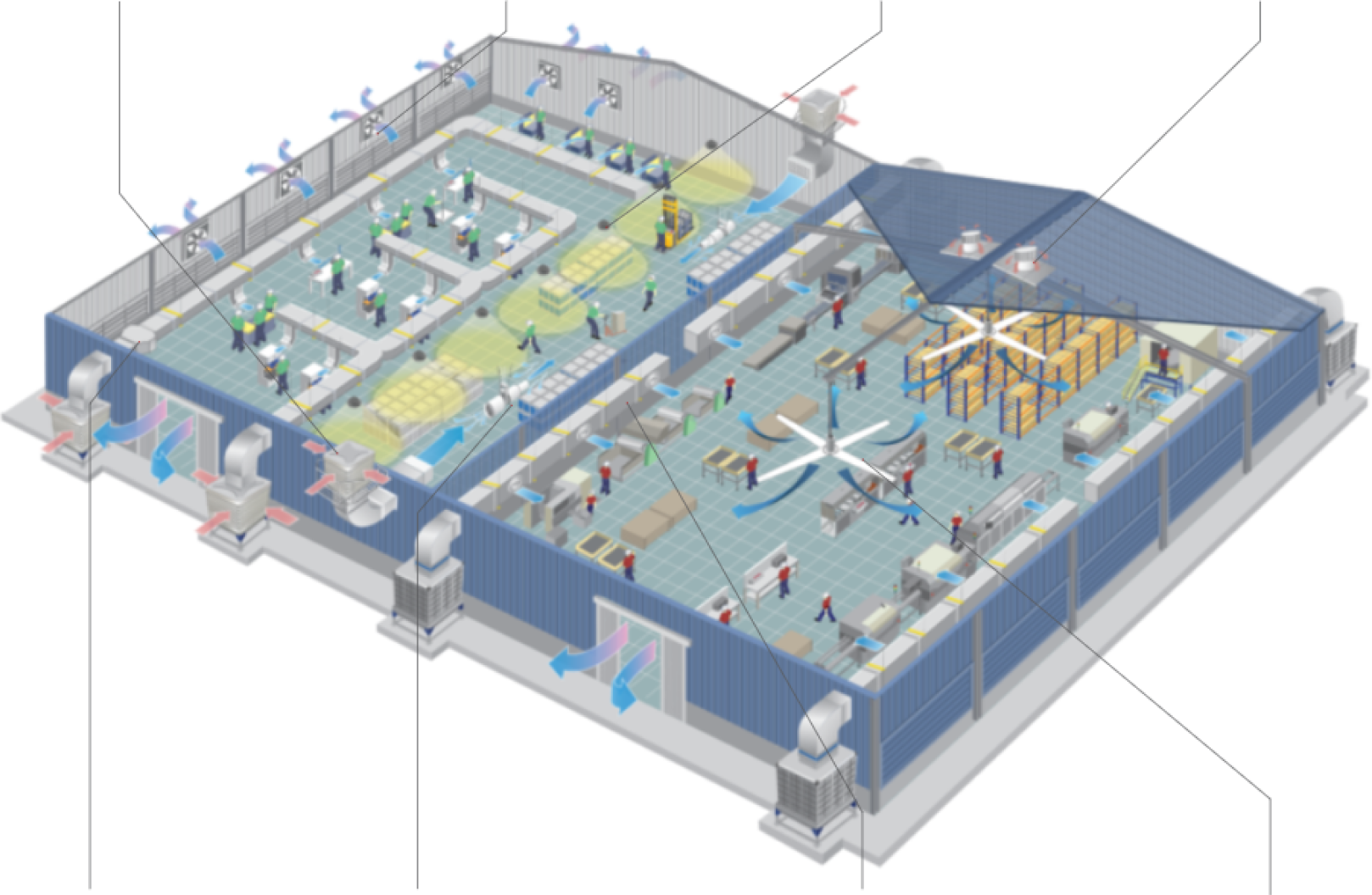

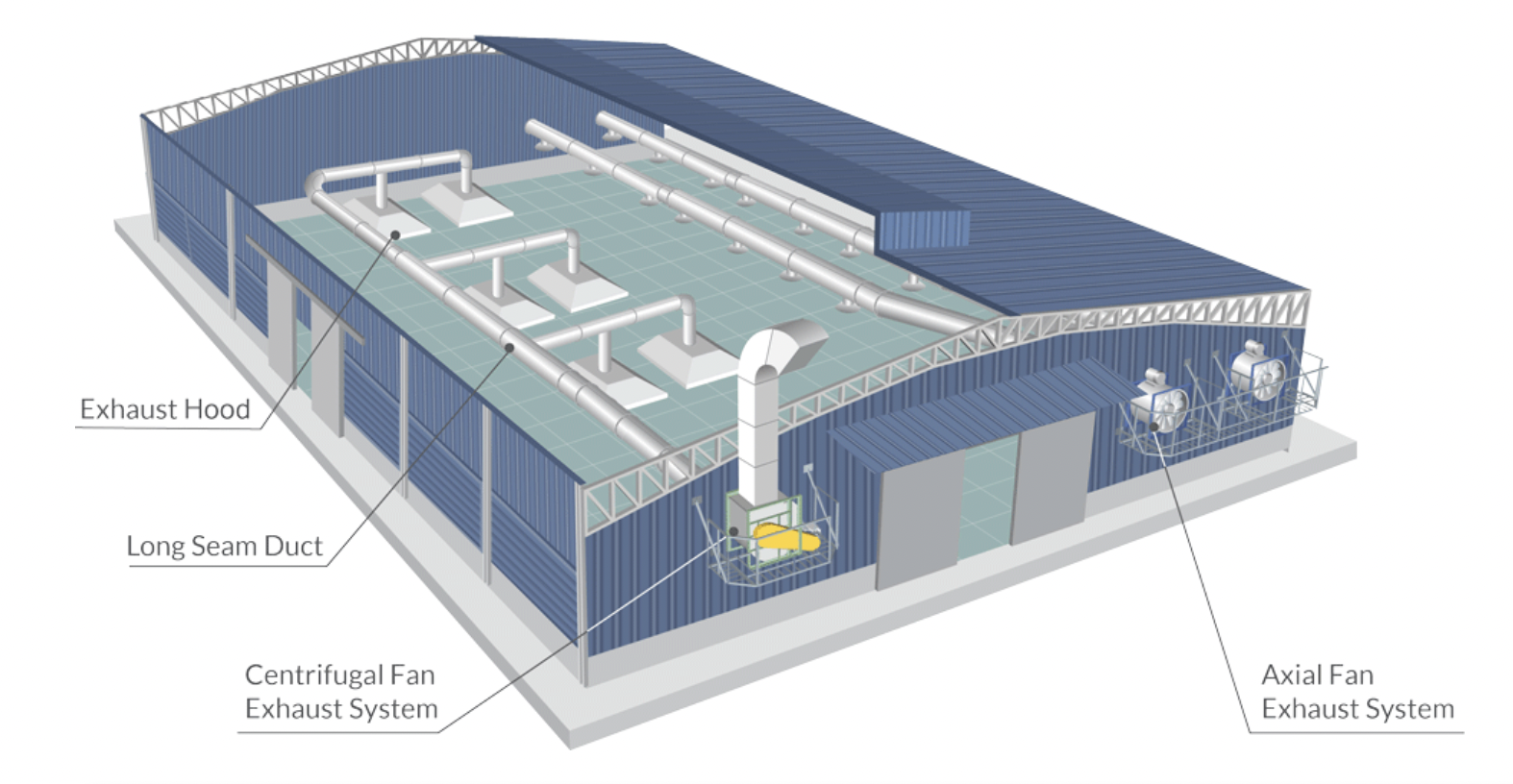

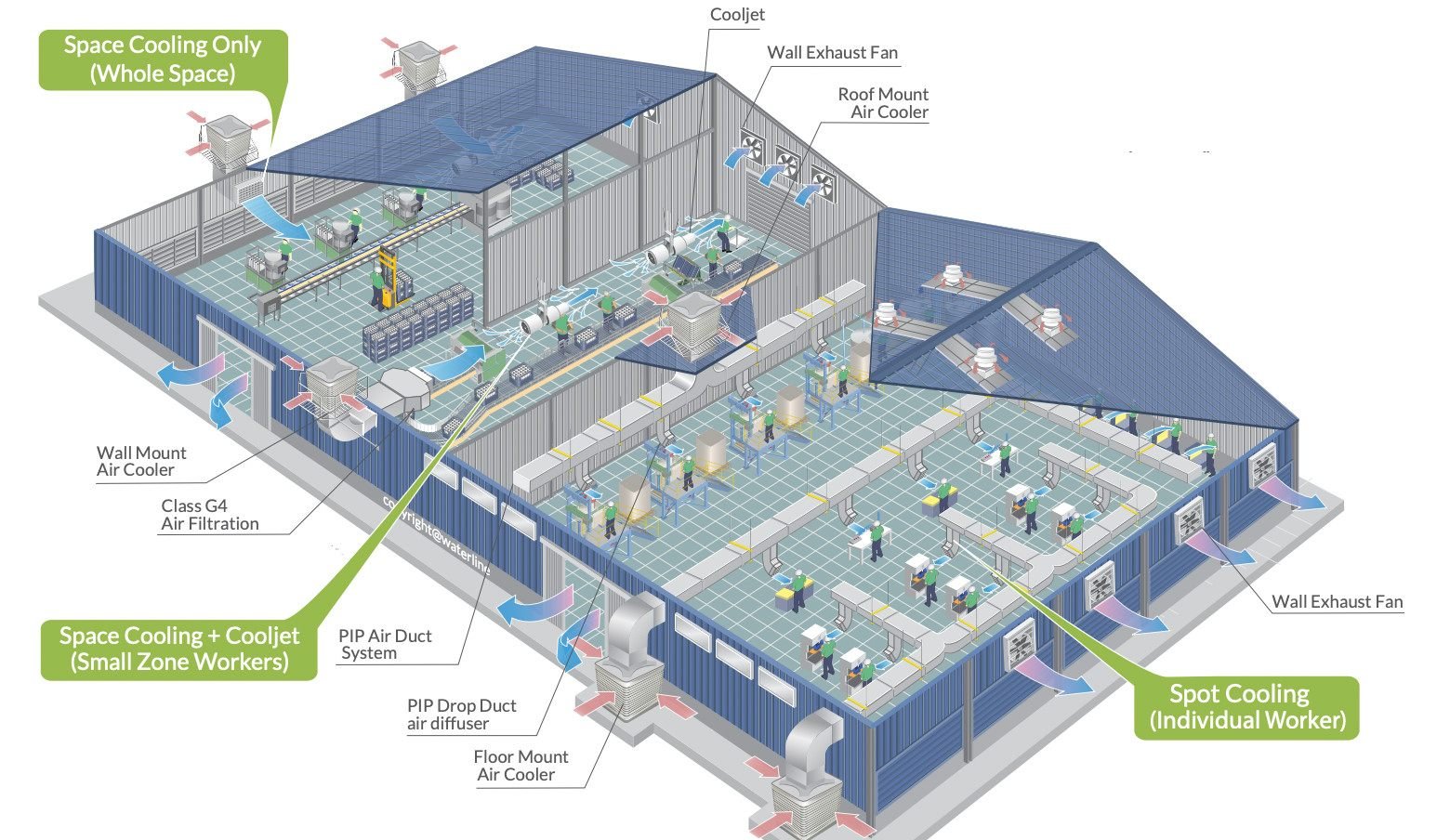

Chúng tôi TIE VIỆT NAM luôn mang đến những giải pháp cải tạo tối ưu cho chi phí quản trị doanh nghiệp và môi trường làm việc cho công nhân của bạn được tốt nhất như: Cải tạo môi trường làm việc cho công nhân bằng việc cung cấp hệ thống Làm Mát không khí, Hút mùi, Hút khí nóng, Khí ô nhiễm. Đồng thời cung cấp giải pháp tiết kiệm chi phí vận hành cho doanh nghiệp bằng công nghệ mới Điện Phân và Từ Trường cho chiller, tháp giải nhiệt, lò hơi. Cùng với đó chúng tôi cung cấp đội ngũ sửa chữa bảo dưỡng bao gồm máy CNC, hệ thống vấn hành khác… Chúng tôi cung cấp cho bạn các loại dầu bảo quản, cắt gọt, đột dập tốt nhất. Hệ thống sàn nâng tự động cho kho bãi của nhà máy.